愛德華MGH 8106高精度系列三坐標測量機報價、產品信息

產品概述:

MGH系列三坐標測量機由固定橋式和移動工作臺組成,其牢固的機械結構確保了系統具備大的剛性、穩定性和小的振動,保證了整個測量空間極高的測量精度。

產品特點:

1) 采用封閉框架結構設計,通過先進的有限元分析,對結構進行優化和設計,保證了整個測量空間的測量精度

2) X、Y、Z三軸導軌均采用行業優質材料,三軸具有相同的溫度效應,保證了測量機精度。

3) 三軸采用進口超精密光柵系統為測量機提供了準確可靠的長度計量基準,光柵系統在結構布局上更符合阿貝原則,保證了機器測量精度。

4) 平衡重力技術,可實現隨時調節平衡重力,提高了運動平穩性及動態測量精度。

5) 配置了精密級氣源過濾器,保證了花崗巖氣浮導軌安全可靠運行。

6) 驅動系統采用知名品牌的高性能電機、先進的傳動裝置, 確保傳動更快捷、更精準、運動性能更佳;

7) 配置了自動實時溫度補償系統。

來源:西安愛德華測量設備股份有限公司 http://www.china-aeh.com

原文地址:http://www.china-aeh.com/html/2013/chaogaojd_0114/5.html,轉載請注明出處產品尺寸圖:![]()

![]()

JPDS4000壓力變送器,工業級壓力變送器,一體化壓力變送器,高精度壓力變送器

壓力變送器壓力敏感核心采用了高性能的硅壓阻式壓力充油芯體,內部的專用集成電路將傳感器毫伏信號轉換成標準遠距離的傳輸電流信號,可以直接與計算機接口卡、控制儀表、智能儀表或PLC等方便相連。該系列產品廣泛應用于工業過程控制、石油、化工、冶金等行業。

1 主要技術參數

⑴ 工作溫度:-20℃~80℃;

⑵ 變送器的準確度等級分為:

0.1級,基本誤差為±0.1;

0.3級,基本誤差為±0.3;

0.5級,基本誤差為±0.5(基本誤差以量程的百分數表示)。

⑶ 熱零點漂移

環境溫度偏離參比工作條件時,變送器的零點漂移應不大于0.03%FS/℃。

⑷ 熱靈敏度漂移

環境溫度偏離參比工作條件時,變送器的滿量程漂移應不大于0.03%FS/℃。

⑸ 絕緣電阻

在參比工作條件下,變送器各端子對地之間的絕緣電阻不得低于50MΩ/250V。

2 外形及安裝

外形結構見圖1,該壓力變送器由殼體,

放大器,接線端子組成,根據用戶的需要

可以選用指針表,液晶表頭顯示。

圖1

3 安裝方法

⑴ 選擇易于操作、維護的地方進行安裝;

⑵ 應盡量遠離振動源安裝;

⑶ 應盡量遠離熱源的地方安裝;

⑷ 直接安裝在管道或設備上,安裝時用扳手夾緊在變送器六方處。

4 電氣連接

打開儀表后蓋(接線端子面),見接線端子,電源連接見圖2:

圖2

5 零點,增益調節

零點及增益的調整方法:

壓力表在出廠前,已經過標定,無須用戶再次調整。若在使用過程中發生零位和滿量程偏離,規定每年校檢,可以在高一級精度的壓力源上重新標定。方法如下:

在無壓力的情況下,調整調零Z電位器,使電流輸出為4.000mA。加滿量程壓力,調整增益S電位器,使電流輸出為20.000mA。如此反復多次,最終使壓力表的零位和滿量程調整到標準值。

6 安全使用注意事項

⑴ 搬運與安裝變送器時應小心謹慎,避免碰撞而影響電路的性能。

⑵ 變送器進壓口內有隔離膜片,切勿人為用異物觸碰。

⑶ 變送器外螺紋處一定要注意密封,否則會造成壓力不準不穩。

⑷ 安全柵須取得防爆合格證,其安裝應按其說明書的要求進行。

⑸ 在產品安裝使用中如遇到問題請與我公司聯系,在產品發生異常時,請不要擅自打開進行修理,應及時與廠家聯系。

CX-M2SS廠家供應專利產品微小液體橢圓齒輪流量計 高精度微小液體橢圓齒輪流量計

微小流量計

應用

微小流量計廣泛用于各種行業的低流量精準測量,如汽車,航空,礦山,電力,油漆和石油等,應用包括燃料,燃料油

潤滑劑,酒精,生物,乙醇燃料,油脂,粘結劑,油墨,殺蟲劑和泵送或重力給料的非導電液體.

定量添加,機器人膠水,液壓,大電機,噴油嘴,油泵試驗臺等各種小流量計的測試應用

產品描述

微小流量計在抗高溫,抗高壓上,采用國際上最先進的設計,讓國產微小流量計不僅在質量上與國際先進水平同步,也在抗高溫,抗高壓上與國際先進水平同步。

微小流量計擁有2項國家發明專利,在生產質量控制過程中,從原材料采購開始,對每一個生產及精密加工環節進行認真仔細的檢查,每一臺微小流量計出廠前必須進行連續校準測試。微小輪流量計各道工序嚴格按照ISO9001質量管理體系嚴格執行,產品擁有CE,SGS等歐盟認證。

我們公司以“德國的品質,中國的價格”為口號打造世界一流的橢圓齒輪流量的,實實在在的做自動化儀表行業中的標桿企業。

技術參數

| 型號 | 流量范圍 | 連接方式 |

| CX-M2 | 0.5~150mL/min | G1/8 內螺紋 |

| CX-M3 | 3~300mL/min | G1/8 內螺紋 |

| CX-M5 | 5~1000mL/min | G1/8 內螺紋 |

| CX-M6 | 0.5~100L/H | G1/4 內螺紋 |

| CX-M9 | 6~600L/H | G1/4 內螺紋 |

| CX-M12 | 0.3~30L/min | G1/2 內螺紋 |

| CX-M25 | 0.5~100L/min | G1內螺紋 |

| CX-M40 | 10~250L/min | G1.5內螺紋 |

| CX-M50 | 15~500L/min | G2 內螺紋 |

| 介質 | 耐強酸,強堿,柴油,膠水,潤滑油,水,乙醇,植物油,蜂蜜,化妝水,藥劑等各種化工化學液體. | |

| 精度 | 0.50% | |

| 溫度 | -30℃到80℃ | |

| 壓力 | 32Bar(可以定制高壓) | |

| 輸出 | 方波脈沖 | |

| 供電 | 4~26VDC | |

| 材質 | 不銹鋼材質,鋁材質 | |

http://www.stoneflowmeter.com/message.shtml

產品特點

上海基深儀器儀表有限公司引進德國西門子CNC數控加工中心,使微小流量計的大大提高,實際上已經達到世界領先水平,很自信的說 精度高壓日本同類產品一倍以上。微小流量計上,小到一個螺絲孔,大到表殼和齒輪都是采用德國西門子CNC數控加工中心來完成,完全擺脫了國內目前靠機械與手工混合操作的制造工藝,微小流量制造工藝將發生里程碑式的變化。

-

中國首家,世界10生產商之一

-

阿里巴巴10年金牌供應商

-

CNC數控切割精度0.001mm.脈沖0.01ml/p.

-

可以替代,日本(OVAL),意大利(Plusi),德國(Kobold).澳大利亞(Flomec).美國(DEA).

-

溫度-20-200℃.壓力150mpa.使用壽命8年.免維護,

-

超50種介質測試,使用工況超100種

K5134D模塊化,高精度,極低溫漂,工業級的信號隔離放大器

廣州際唯JWI200高精度雙軸傾角傳感器

產品簡介

JWI200是一款高精度雙軸傾角傳感器,采用動態零位測試補償技術保證產品快速啟動,分辨率高、數據穩定、承受沖擊震動能力強;內置32位ARM處理器,快速濾波運算,輸出低精度數據;本傾角傳感器設計有抗電磁干擾電路,系統工作穩定,能長期工作于惡劣環境中。

參數規格

| 精度 | 0.001° | 測量范圍 | ±15° |

| 測量軸 | X-Y | 刷辨率 | 1Hz |

| 沖擊 | 20000g, 1ms, ½sine | 響應頻率 | 在DC response時為5-300HZ |

| 波特率 | 4800~11520 | 零點漂移 | 在-25~85℃時為±0.0007°/℃ |

| 工作溫度 | -40~+55℃ | 存儲溫度 | -60~+80℃ |

| 交插靈敏度 | 在Max時為2% | 輸出阻抗 | 100Ω |

| 電源電壓 | 5~12VDC | 消耗電流 | ±50mA |

適用領域

- 雷達及天線角度檢測

- 桿塔、橋梁、山體、大壩監測

- 工程機械臂姿態檢測

- 車輛、船舶姿態檢測

- 電子水平臺等

- 高空平臺保護

更多信息

請登錄:www.jiweikeji.com

S-20WIKA S-20 高精度 高壓力范圍 壓力變送器 精度:0.125 1600bar

| 接口尺寸: | G1/2(mm) | 加工定制: | 是 |

| 防護等級: | IP65 | 測量范圍: | 0-160000(kPa) |

| 類型: | 陶瓷型壓力變送器 | 防爆等級: | EX |

| 型號: | S-20 | 測量介質: | 液體 氣體 |

| 精度等級: | 0.125 | 品牌: | WIKA/威卡 |

| 輸出信號: | 4-20(mA) | 電源電壓: | 10-30(V) |

WIKA S-20 高精度 高壓力范圍 壓力變送器

精度:0.125 1600bar

Superior pressure transmitter for general industrial applicationsModel S-20

Applications Critical industrial applications Demanding applications in research and development Harsh environments in the process industry

Applications Critical industrial applications Demanding applications in research and development Harsh environments in the process industry

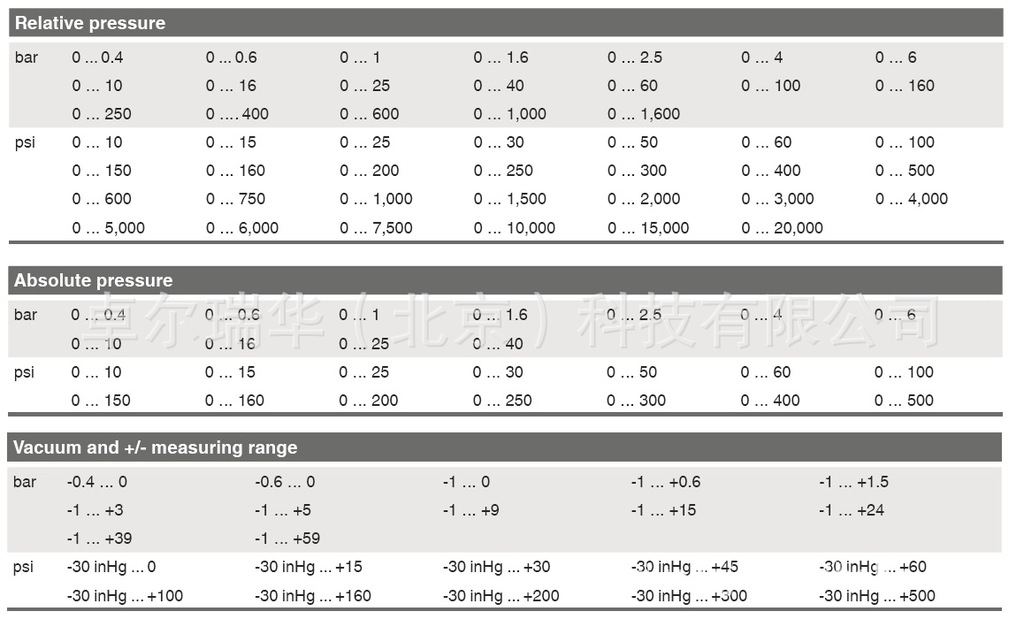

Special features Measuring ranges from 0 ... 0.4 to 0 ... 1,600 bar Non-linearity of up to 0.125 % of span Different output signals, e.g. 4 ... 20 mA, DC 0 ... 10 V,

DC 1 ... 5 V and others Market-standard electrical connections, e.g. DIN 175301-803 A angular connector Common international process connections

Description The model S-20 pressure transmitter for general industrial applications is the ideal solution for customers with demanding measuring requirements. It features a very good accuracy, a robust design and an exceptional number of variants, meaning it can be suited to the widest range of applications.

Versatile The model S-20 offers continuous measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar in all the major units. These measuring ranges can be combined in almost any way with all the standard industry output signals, the most common international process connections and a wide number of electrical connections. Furthermore, it offers numerous options, such as different accuracy classes, extended temperature ranges and customer-specific pin assignments.

High quality The robust design turns the model S-20 into a very high quality product, which even the most adverse environmental conditions cannot affect. Whether with the lowest temperatures when used outdoors, with extreme shock and vibration in machine building or with aggressive media in the chemical industry, this transmitter can meet all requirements.

Availability All variants described in this data sheet are available on very short lead times. For particularly urgent demands, there is a sizeable stock available.

Measuring ranges

The given measuring ranges are also available in kg/cm2, kPa and MPa. Special measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar are available on request. Special measuring ranges have a reduced long-term stability and increased temperature errors.

The given measuring ranges are also available in kg/cm2, kPa and MPa. Special measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar are available on request. Special measuring ranges have a reduced long-term stability and increased temperature errors.

Overpressure limit The overpressure limit is based on the sensor element used. Depending on the selected process connection and sealing, restrictions in overpressure safety can result. A higher overpressure limit will result in a higher temperature error.

Measuring range < 10 bar/150 psi ≥ 10 bar/150 psi 3 times (standard) 2 times 1) (standard) 5 times 3 times 2) 3) 1) Restriction: max. 60 bar/870 psi with absolute pressure 2) Only possible for relative pressure measuring ranges ≤ 400 bar or 5,800 psi 3) Only possible for absolute pressure measuring ranges < 16 bar or 220 psi

Measuring range < 10 bar/150 psi ≥ 10 bar/150 psi 3 times (standard) 2 times 1) (standard) 5 times 3 times 2) 3) 1) Restriction: max. 60 bar/870 psi with absolute pressure 2) Only possible for relative pressure measuring ranges ≤ 400 bar or 5,800 psi 3) Only possible for absolute pressure measuring ranges < 16 bar or 220 psi

Vacuum tightness Yes

Output signal

Signal type Signal Current (2-wire) 4 ... 20 mA 20 ... 4 mA Voltage (3-wire) DC 0 ... 10 V DC 0 ... 5 V DC 1 ... 5 V DC 0.5 ... 4.5 V DC 1 ... 6 V DC 10 ... 0 V Ratiometric (3-wire) DC 0.5 ... 4.5 V

Other output signals on request.

Permissible load in Ω Current output (2-wire): ≤ (power supply - 7.5 V) / 0.023 A ≤ (power supply - 11.5 V) /

0.023 A (with optional settling time of 1 ms) Voltage output (3-wire): > maximum output voltage / 1 mA Ratiometric output (3-wire): > 4.5k

Signal limiting (option) 4 ... 20 mA: Zero point: 3.6 mA 1), 3.8 mA, 4.0 mA Full scale: 20 mA, 21.5 mA, 23 mA DC 0 ... 10 V: Full scale: DC 10 V, DC 11.5 V 1) Not possible in combination with zero point adjustment by the customer

Voltage supply

Power supply Maximum power supply for cULus approval: DC 35 V (DC 32 V with heavy-duty connector) Current output (2-wire) 4 ... 20 mA: DC 8 ... 36 V (DC 12 ... 36 V with optional settling time of 1 ms) 20 ... 4 mA (inverted): DC 8 ... 36 V Voltage output (3-wire) DC 0 ... 10 V: DC 12 ... 36 V DC 0 ... 5 V: DC 8 ... 36 V DC 1 ... 5 V: DC 8 ... 36 V DC 0.5 ... 4.5 V: DC 8 ... 36 V DC 1 ... 6 V: DC 9 ... 36 V DC 10 ... 0 V: DC 12 ... 36 V Ratiometric output (3-wire): DC 0.5 ... 4.5 V: DC 5 V ±10 %

Dissipation loss Current output (2-wire): 828 mW (22 mW/K derating of the dissipation loss with ambient temperatures ≥ 100 °C) Voltage output (3-wire): 432 mW

Current supply Current output (2-wire): Current signal, max. 25 mA Voltage output (3-wire): max. 12 mA

Reference conditions (per IEC 61298-1)

Temperature 15 ... 25 °C

Atmospheric pressure 860 ... 1,060 mbar

Humidity 45 ... 75 % relative

Power supply DC 24 V DC 5 V with ratiometric output

Mounting position Calibrated in vertical mounting position with pressure connection facing downwards.

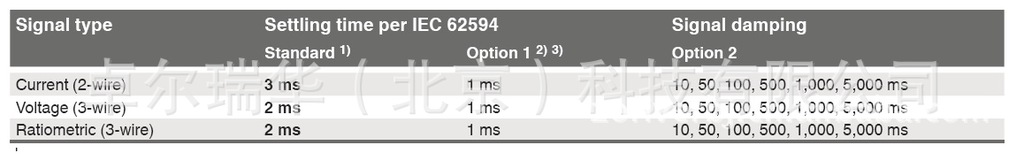

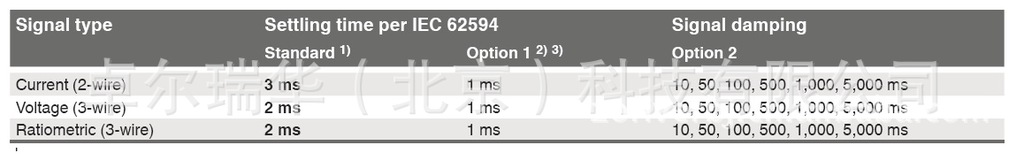

Time response  1) 3 dB limit frequency: 500 Hz2) 3 dB limit frequency: 1,000 Hz3) Alternative specifications for 4 ... 20 mA output signal: Load: ≤ (power supply - 11.5 V) / 0.023 A Power supply: DC 12 ... 36 V

1) 3 dB limit frequency: 500 Hz2) 3 dB limit frequency: 1,000 Hz3) Alternative specifications for 4 ... 20 mA output signal: Load: ≤ (power supply - 11.5 V) / 0.023 A Power supply: DC 12 ... 36 V

Switch-on time 150 ms

Switch-on drift 5 s (60 s with optional zero point adjustment 0.1 %)

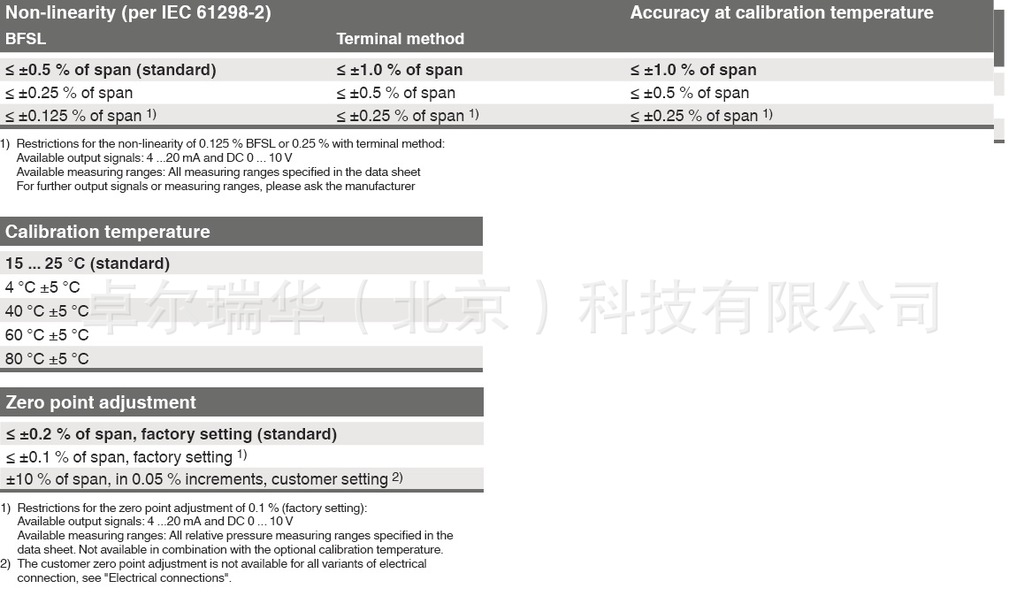

Accuracy data

Relationship to the mounting position For measuring ranges < 1 bar/15 psi, an additional zero offset of up to 0.15 %applies

Non-repeatability ≤ ±0.1 % of span

Temperature hysteresis 0.1 % of span at > 80 °C

Long-term drift (per IEC 61298-2) ≤ ±0.1 % of span ≤ ±0.2 % of span (with special measuring ranges)

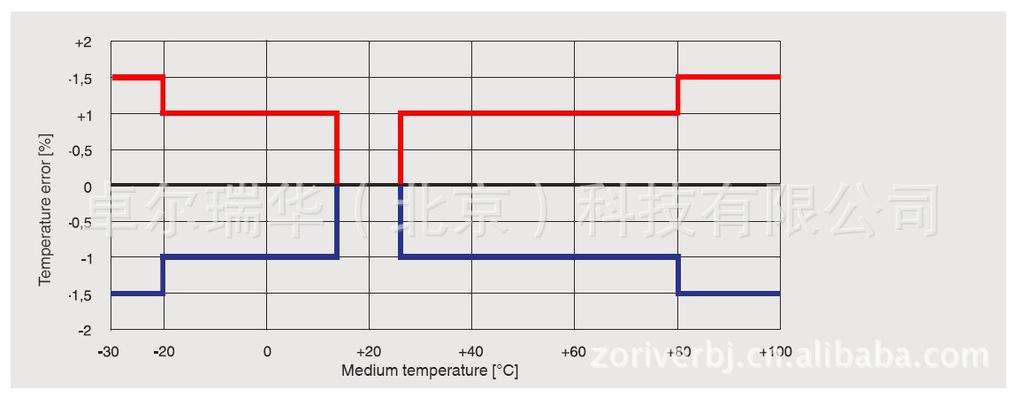

Temperature error (for calibration temperature of 15 ... 25 °C) For measuring ranges < 1 bar, special measuring ranges and instruments with an increased overpressure limit the respective temperature error increases by 0.5 % of span

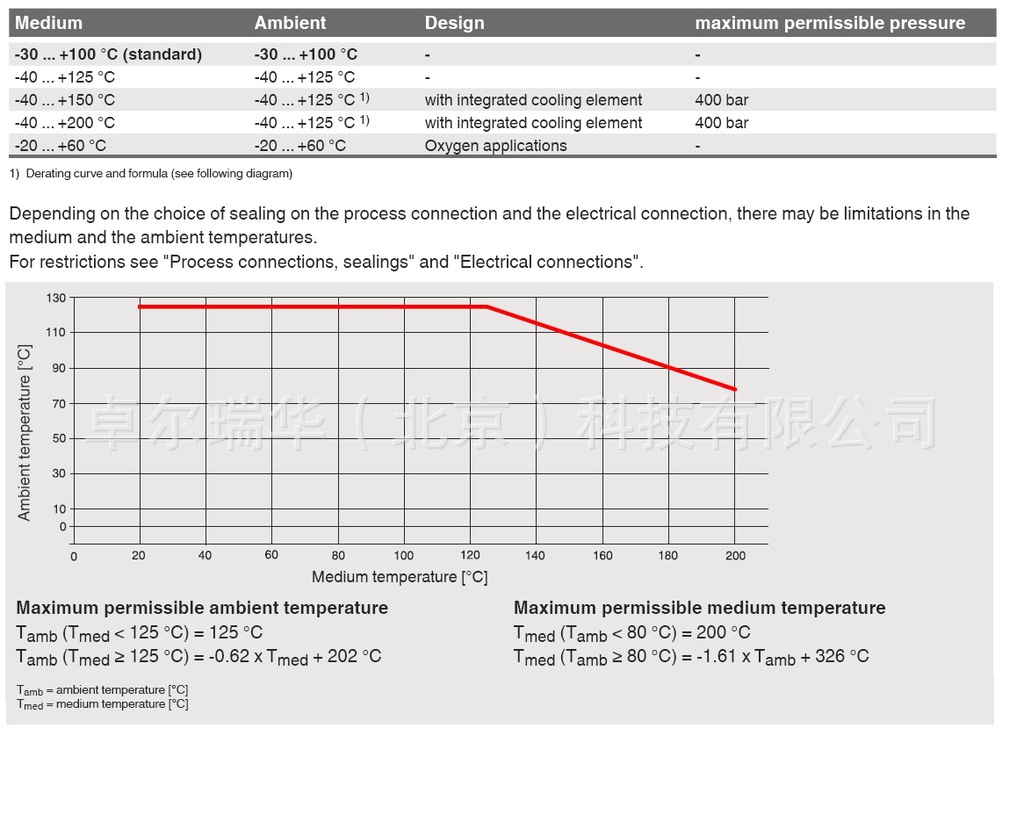

Operating conditions Permissible temperature ranges

Operating conditions Permissible temperature ranges

Storage and transport conditions Permissible temperature range: -40 ... +70 °C Maximum humidity (per IEC 68-2-78): 67 % r.h. at 40 °C (in accordance with 4K4H per EN 60721-3-4)

Storage and transport conditions Permissible temperature range: -40 ... +70 °C Maximum humidity (per IEC 68-2-78): 67 % r.h. at 40 °C (in accordance with 4K4H per EN 60721-3-4)

Climate class Storage: 1K3 (per EN 60721-3-1) Transport: 2K2 (per EN 60721-3-2) Operation: 4K4H (per EN 60721-3-4, without condensation or icing)

Vibration resistance (per IEC 68-2-6) 20 g, 10 ... 2,000 Hz, (40 g, 10 ... 2,000 Hz for heavy-duty connector) For instruments with cooling elements a limited vibration resistance applies 10 g (10 ... 2,000 Hz)

Continuous vibration resistance (per IEC 68-2-6) 10 g

Shock resistance (per IEC 68-2-27) 100 g, 6 ms (500 g, 1 ms for heavy-duty connector)

Service life 100 million load cycles (10 million load cycles for measuring ranges > 600 bar/7,500 psi)

Free-fall test (following IEC 60721-3-2) Individual packaging: 1.5 m Multiple packaging: 0.5 m PE bag: 0.5 m

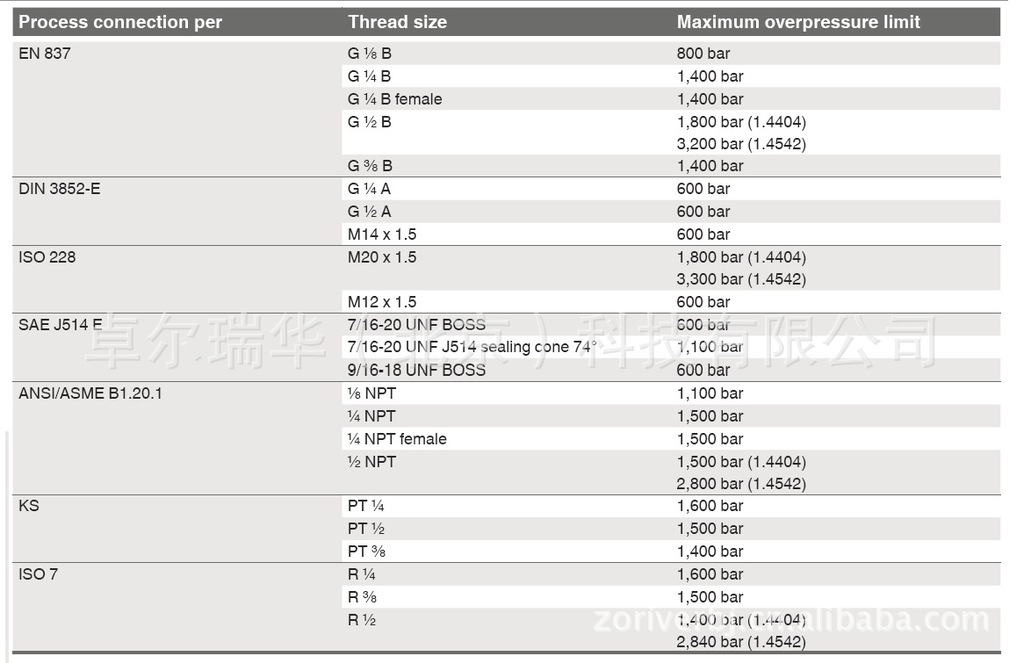

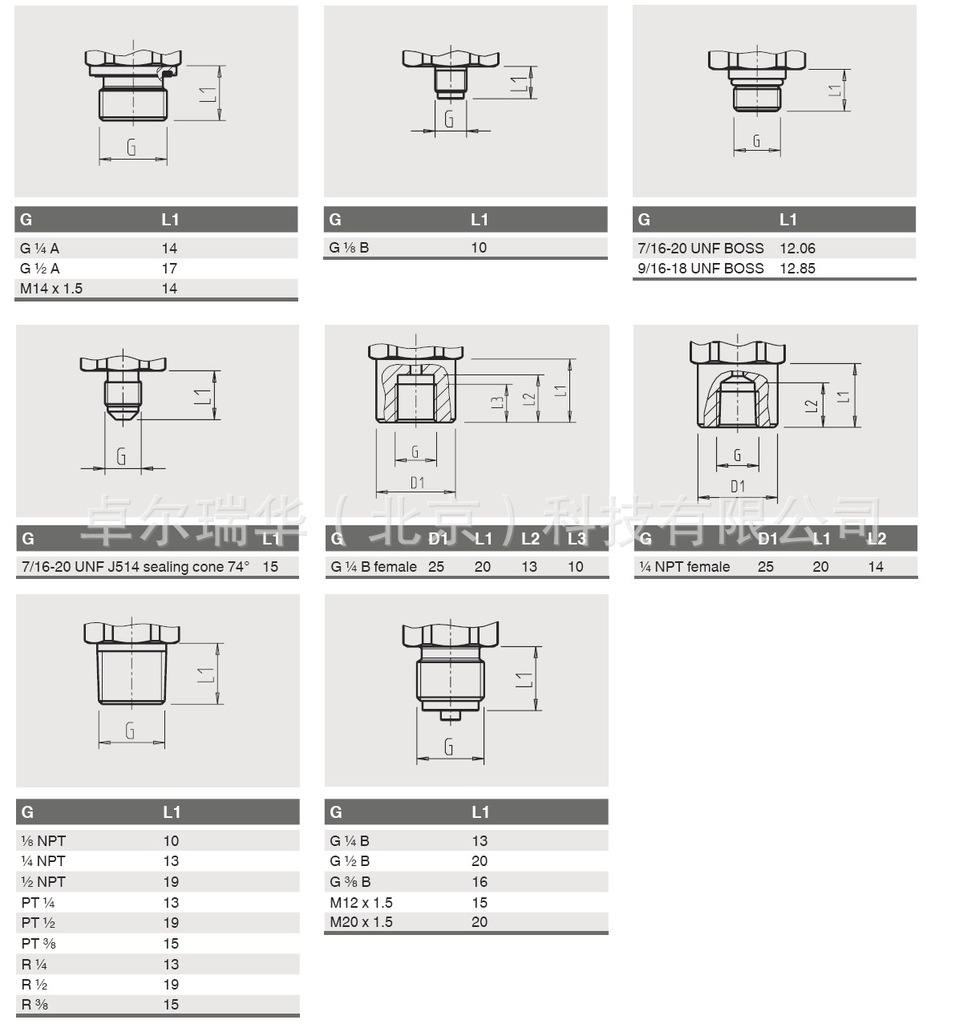

Process connections Available connections

Other process connections on request.

Other process connections on request.

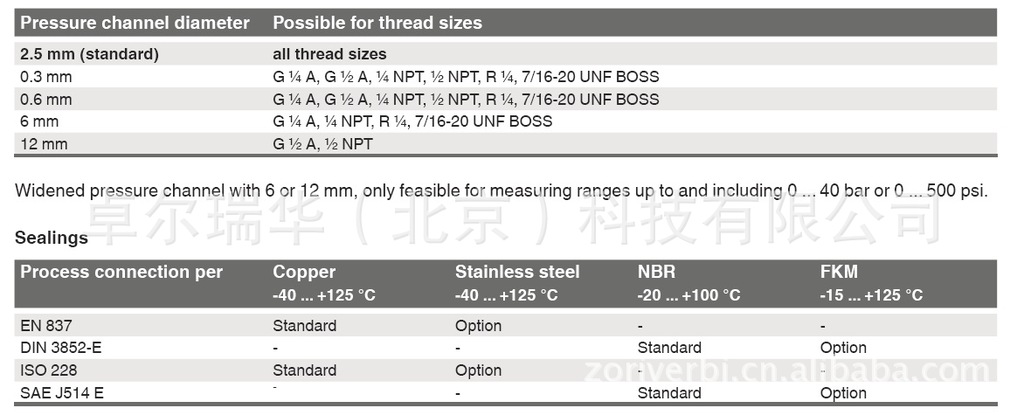

Process connections

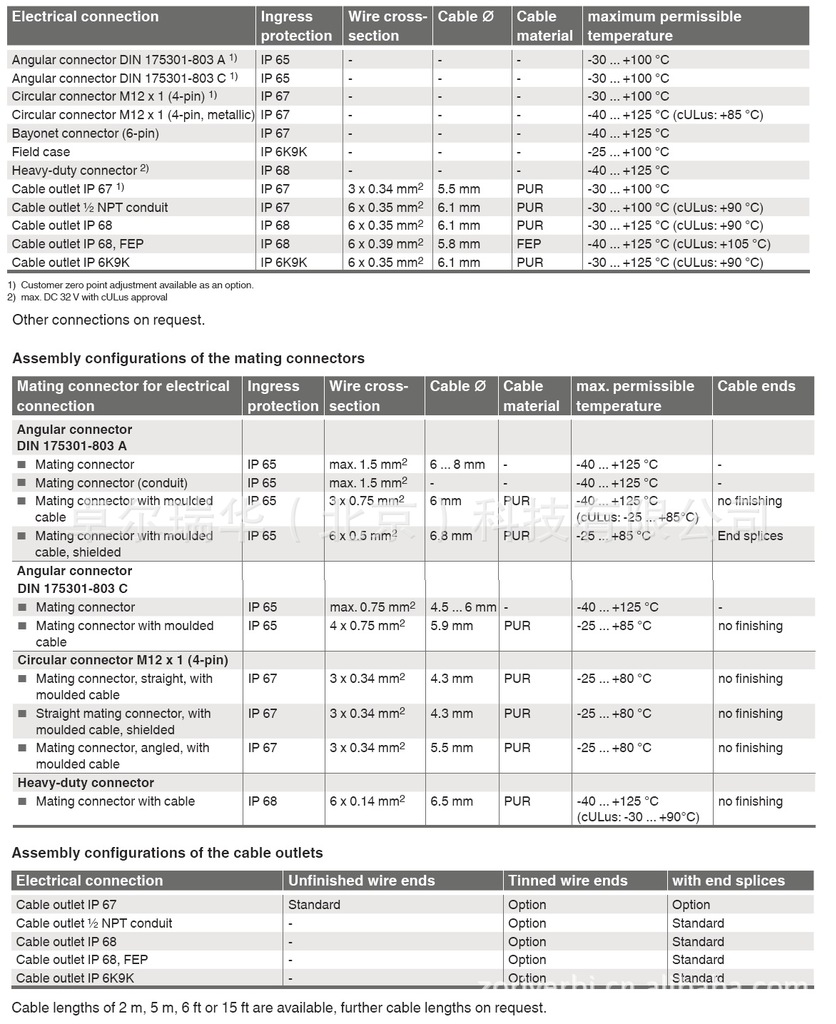

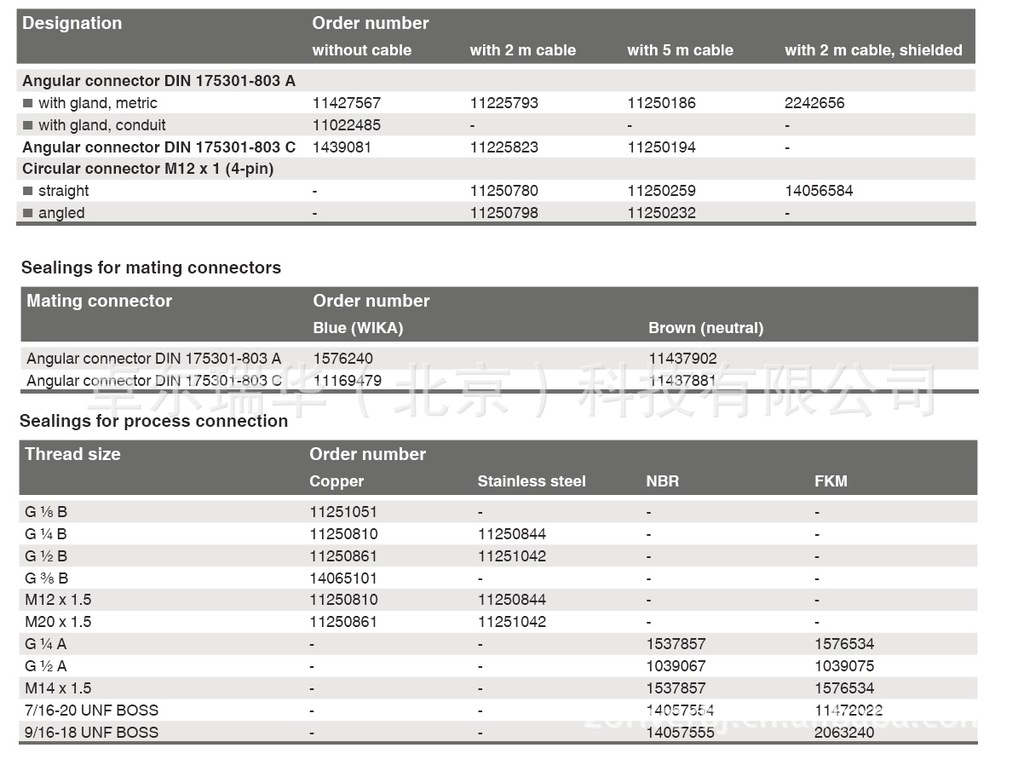

Electrical connections

Available connections

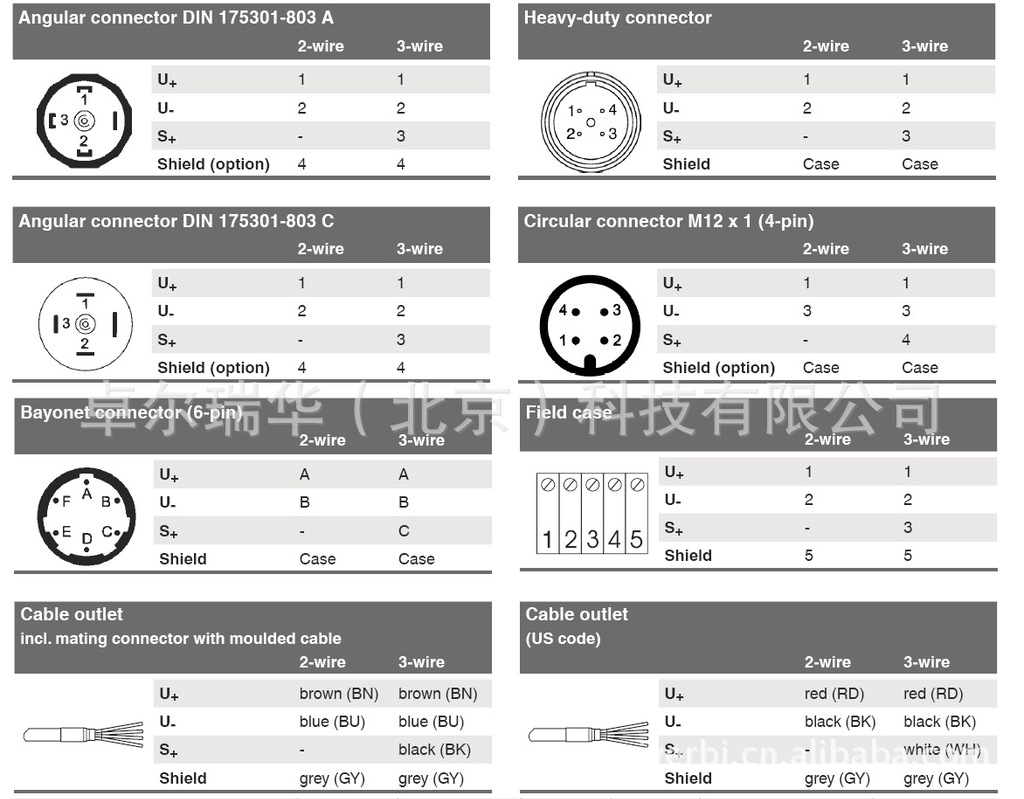

Connection diagrams

Connection diagrams

Other pin assignments on request.

Other pin assignments on request.

Electrical protective measures The electrical protective measures are not valid for ratiometric output signals. Short-circuit resistance: S+ vs. U- Reverse polarity protection: U+ vs. U- Resistance to overvoltage: DC 40 V Insulation voltage: DC 750 V

Materials

Wetted parts Relative measuring ranges: - Measuring ranges ≤ 10 bar/150 psi: 316L - Measuring ranges > 10 bar/150 psi: 316L + 13-8 PH Absolute pressure measuring ranges: - Measuring ranges ≤ 1,000 bar/10,000 psi: ASTM 630 and 13-8 PH - Measuring ranges > 1,000 bar/10,000 psi: 316L + 13-8 PH Sealing materials: see "Process connections"

Non-wetted parts Case: 316 Ti Zero point adjustment ring: PBT/PET GF30 Electrical connections: Angular connector DIN 175301-803 A: PBT/PET GF30 Angular connector DIN 175301-803 C: PBT/PET GF30 Circular connector M12 x 1 (4-pin): PBT/PET GF30 Circular connector M12 x 1 (4-pin, metallic): 316L Bayonet connector (6-pin) 316L + Al Field case: 316L, 316Ti Heavy-duty connector: 316L Cable outlet IP 67: PA66 Cable outlet ½ NPT conduit: 316L Cable outlet IP 68: 316L Cable outlet IP 68, FEP: 316L

Cable outlet IP 6K9K: 316L

Pressure transmission fluid Synthetic oil (for measuring ranges < 10 bar/150 psi relative and absolute pressure)

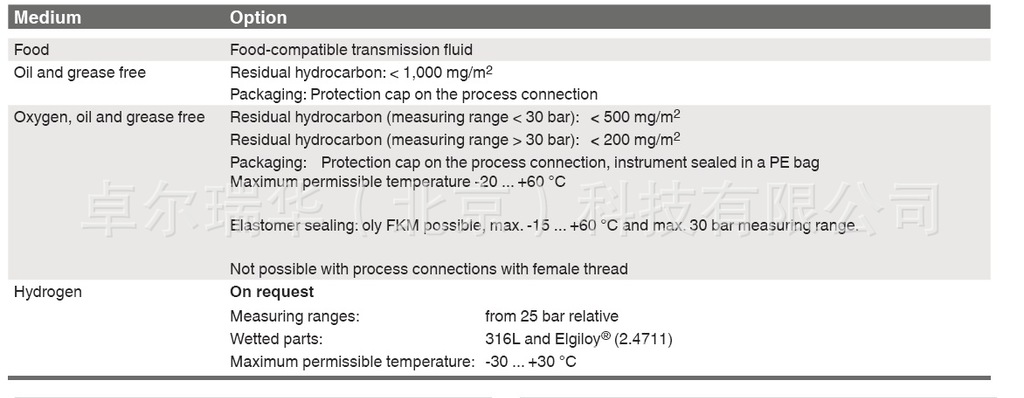

Options for specific media

CE conformity

CE conformity

Pressure equipment directive 97/23/EC

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and interference immunity (industrial application)

EM field 30 V/m (80 ... 1,000 Mhz)

RoHS conformity Directive 2002/95/EC

Performance level (per EN ISO 13849-1:2008) Performance level: PL = C Category: Cat. = 1 Diagnostic coverage: DC = none MTTF: > 100 years

Certificates (option)

Available certificates 2.2 test report State-of-the-art manufacturing Wetted metallic parts Confirmation of the class and indication accuracy 3.1 inspection certificate Wetted metallic parts Wetted metallic parts with suppliers' certificate Confirmation of the class and indication accuracy List of single measured values DKD/DAkkS calibration certificate Certificates, see website

Scope of delivery

Test report Non-linearity 0.5 % 3 points Non-linearity 0.25 % 5 points Non-linearity 0.125 % 5 points

Packaging Individual packaging (standard) Multiple packaging (up to 20 pieces)

Instrument labelling WIKA label lasered (standard) Customer-specific label on request

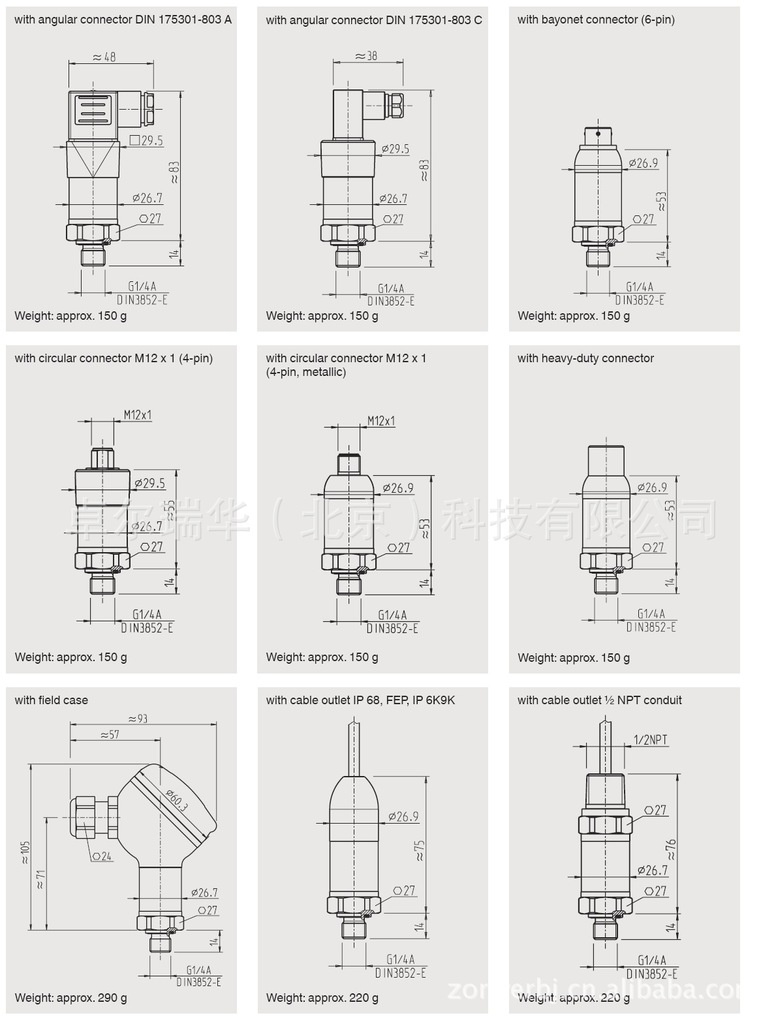

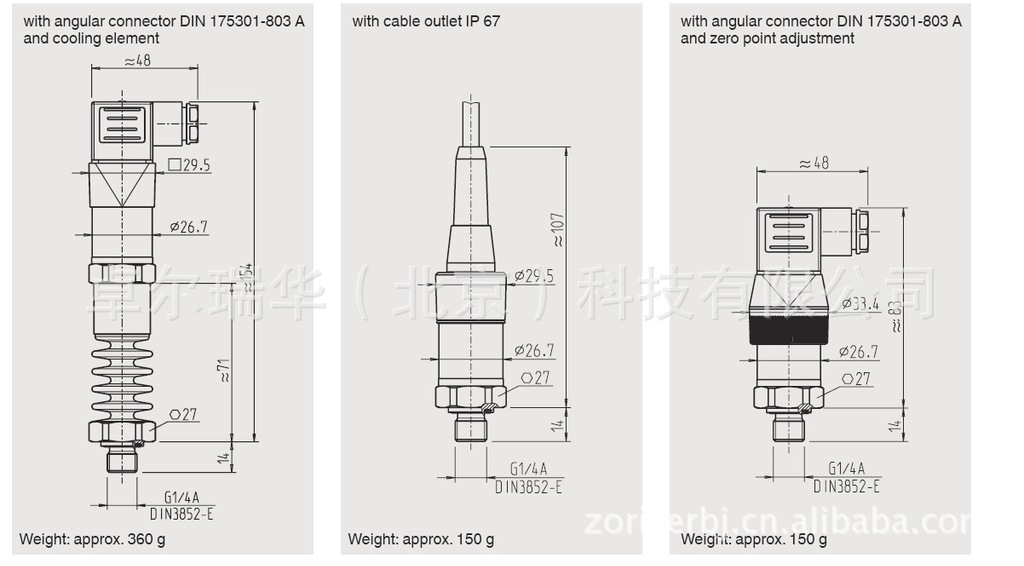

Dimensions in mm Pressure transmitter model S-20

Process connections

Process connections

Accessories and spare parts

Mating connector  Ordering information Model / Measuring range / Overpressure limit / Output signal / Non-linearity / Calibration temperature / Zero point adjustment/ Process connection / Pressure channel / Sealing / Electrical connection / Assembly / Cable length / Shielding / Certificates /Packaging / Instrument labelling / Accessories and spare parts

Ordering information Model / Measuring range / Overpressure limit / Output signal / Non-linearity / Calibration temperature / Zero point adjustment/ Process connection / Pressure channel / Sealing / Electrical connection / Assembly / Cable length / Shielding / Certificates /Packaging / Instrument labelling / Accessories and spare parts

歡迎致電咨詢定購WIKA S-20 高精度 高壓力范圍 壓力變送器 精度:0.125 1600bar

電話: 56291930 15910733293

傳真:

QQ:823377546 1491421115 2636968574

郵箱:sales@zoriver.cn

公司官網:http://www.zoriver.cn http://www.zoriver.com.cn

FLWG山南高精度測量液體渦輪流量計使用方法

液體渦輪流量計FLWG液體渦輪流量計是吸取了國內外流量儀表先進技術經優化設計,具有結構簡單、輕巧、精度高、復現性好、反應靈敏,安裝維護使用方便等特點的新一代渦輪流量計。當被測流體流過傳感器時,在流體作用下,葉輪受力旋轉,其轉速與管道平均流速成正比,葉輪的轉動周期地改變磁電轉換器的磁阻值。檢測線圈中的磁通隨之發生周期性變化,產生周期性的感應電勢,即電脈沖信號,經放大器放大后,送至顯示儀表顯示。特點:【1】輸出脈沖頻率信號,適于總量計量計與計算機連接,無零點漂移,抗干擾能力強【2】可獲得很高的頻率信號(3-4KHz),信號分辨力強【3】范圍度寬,中大口徑可達1:20,小口徑為1:10【4】結構緊湊輕巧,安裝維護方便,流通能力大【5】專用型傳感器類型多,可根據用戶特殊需要設計為各類專用型傳感器,例如低溫型、雙向型、井下型等【6】工作電源: A 外電源:+24VDC±15%,紋波≤±5%,適用于4-20mA輸出、脈沖輸出、RS485等 B 內電源:1組3.0V10AH鋰電池,電池電壓在2.0v-3.0v時均可正常工作【7】精度等級:1.0、1.5量程比:1:10;1:15;1:20

testo110高精度溫度儀

testo110是一個高精度的溫度儀。加上保護軟套后使110使用于食品,實驗室及冷藏/冷凍部門。它所用的技術是專為在冷藏室,櫥柜及室外使用所設計的。 • 配件套裝1 (用于不配保護軟套的溫度儀):多功能夾、掛繩和探頭夾 • 配件套裝2 (用于配有保護軟套的溫度儀):扣件、探頭夾 • 單位切換:°C/°F • 食品 • 14mm字高顯示、易于讀取 • 低電量顯示 • 保護軟套,可放入洗碗機清洗 • 適用于冷藏過程中的測量 • 高精度溫度儀帶標定證書 • 精度高

測量食品儲存溫度 探頭種類 量程精度實驗室探頭,可更換玻璃套管,耐腐蝕 -50…+150℃ 有撕拉帶的管道探頭,適用最大管徑75mm -50…+70℃ 不銹鋼高溫食品探頭,耐溫+275°C,特氟龍電纜耐溫+200°C (短時間內可達250°C) 0…275℃ 食品探頭,不銹鋼制造(IP67),特氟龍電纜耐溫+200℃(短時間內可達+250℃) -50…+150℃ 冷凍食品探頭,螺紋設計 -50…+140℃ 插入式食品探頭,帶特殊手柄,IP65,加強電纜(PUR),防烘烤 -50…+150℃ 食品探頭(IP65),不銹鋼制造,PUR電纜耐溫+80℃,連接插頭IP54 -50…+150℃ 防水表面探頭,有擴大的測量尖端 -50…+150℃ 空氣探頭,用于檢測倉儲溫度 -50…+150℃ 防水浸入/插入式探頭 -50…+150℃ 技術數據顯示 LCD 操作溫度 0... +40 °C 存放溫度 -20... +70 °C 電池種類 堿性電池9V 電池壽命 100 小時 尺寸 190x57x42 毫米 重量 300 克

保修 1 年

LX-3000Fykky牌分體式冷水機 高精度精美制冷機組

分體式冷水機主要應用原子吸收、激光器、真空鍍膜機、離子刻蝕機、超低溫實驗儀器、氧氮分析儀、X射線衍射儀,液壓源、油源等發熱設備。由于實驗室空間小,制冷機在工作的同時產生了大量的熱量和噪音,為了給科技工作人員創造一個舒適安靜的工作環境,分體式冷水機是很好的選擇。聯系人:136-0107-4786 技術參數:

* 溫度范圍:5~35℃;

* 控溫精度:±0.1℃;

* 制 冷 量:20℃時3000W;

* 水箱容積:40L;

* 循環泵大壓力:0~4.0Bar;

* 循環壓力調節范圍:1.5~3.6Bar;

* 循環泵大流量:0~45L/min;

* 儀器接口尺寸:1/2〞NPT

* 儀器室內機尺寸:W425×D750×H770mm

* 儀器室外機尺寸: W800×D270×H530mm

* 儀器重量: 56KG+45KG

主要特點:

* 溫度、壓力、水位均可顯示;

* 業設計的動態控溫系統,控溫精度高,溫度波動小;

* 簡捷方便的人機操作界面,控制參數自動記憶;

* 各種制冷功率和循環泵壓力,可滿足各類儀器的冷卻和恒溫;

* 制冷系統關鍵部件采用進口名牌產品,工作穩定可靠;

* 多種循環泵可以選配,可選超靜音、高壓力或大流量;

* 循環壓力可調,配不銹鋼壓力指示表;

* 標準不銹鋼接口,可佩多種規格的接頭和軟管,外接閉路循環;

* 可選配加裝RS485通訊,便于連接上位機;

* 可選停電恢復功能,可選流量報警;

最新產品

- 供應磨床支架巴氏合金拖瓦滑塊 2025/5/20 20:48:57

- 上海城市商業街外墻清洗 安裝 拆除 維修 防水 蜘蛛人吊繩高空作業 2025/5/20 20:13:55

- DBY-50P不銹鋼防爆電動隔膜泵, 變頻電動隔膜泵 2025/5/20 19:56:59

- 苯并芘檢測儀器 苯并芘檢測儀器廠家 2025/5/20 19:18:02

- 食用油苯并芘快速檢測儀 2025/5/20 19:17:51

- 苯并芘檢測儀器多少錢 2025/5/20 19:17:38

- 快速檢測苯并芘食用油儀器 快速檢測苯并芘食用油儀器廠家 2025/5/20 19:17:11

- 食用油苯并芘檢測儀器 食用油苯并芘檢測儀器廠家 2025/5/20 19:16:49

- 高智能食用油苯并芘檢測儀 高智能食用油苯并芘檢測儀廠家 2025/5/20 19:16:37

- 多通道苯并芘綜合檢測儀器 多通道苯并芘綜合檢測儀器廠家 2025/5/20 19:16:24

- 測食用油中苯并芘的儀器 測食用油中苯并芘的儀器廠家 2025/5/20 19:16:07

- 測介質損耗工頻介電常數測試儀 2025/5/20 19:10:10

- 人透明質酸合酶2(HAS2) ELISA 試劑盒 2025/5/20 18:50:48

- 人透明質酸合酶2(HAS2) ELISA 試劑盒 2025/5/20 18:50:45

- 人透明質酸合酶1(HAS1) ELISA 試劑盒 2025/5/20 18:50:43

- 人透明質酸合酶1(HAS1) ELISA 試劑盒 2025/5/20 18:50:41

- 人透明質酸結合蛋白2(HABP2) ELISA 試劑盒 2025/5/20 18:50:39

- 人透明質酸結合蛋白2(HABP2) ELISA 試劑盒 2025/5/20 18:50:36

- 人透明質酸結合蛋白1(HABP1) ELISA 試劑盒 2025/5/20 18:50:34

- 人透明質酸結合蛋白1(HABP1) ELISA 試劑盒 2025/5/20 18:50:32

- 人透明質酸酶(HAase) ELISA 試劑盒 2025/5/20 18:50:30

- 人透明質酸酶(HAase) ELISA 試劑盒 2025/5/20 18:50:27

- 人延伸因子極長鏈脂肪酸樣蛋白1(ELOVL1) ELISA 試劑盒 2025/5/20 18:50:25

- 人延伸因子極長鏈脂肪酸樣蛋白1(ELOVL1) ELISA 試劑盒 2025/5/20 18:50:23

- 人DNA甲基轉移酶3B(DNMT3B) ELISA 試劑盒 2025/5/20 18:50:16

- 人DNA甲基轉移酶3B(DNMT3B) ELISA 試劑盒 2025/5/20 18:50:14

- 人DNA甲基轉移酶3A(DNMT3A) ELISA 試劑盒 2025/5/20 18:50:11

- 人DNA甲基轉移酶3A(DNMT3A) ELISA 試劑盒 2025/5/20 18:50:09

- 人DNA甲基轉移酶1(DNMT1) ELISA 試劑盒 2025/5/20 18:50:07

- 人DNA甲基轉移酶1(DNMT1) ELISA 試劑盒 2025/5/20 18:50:04

SBC托利多傳感器 稱重顯示儀表 托利多稱重模塊

SBC托利多傳感器 稱重顯示儀表 托利多稱重模塊